Small hydro generators

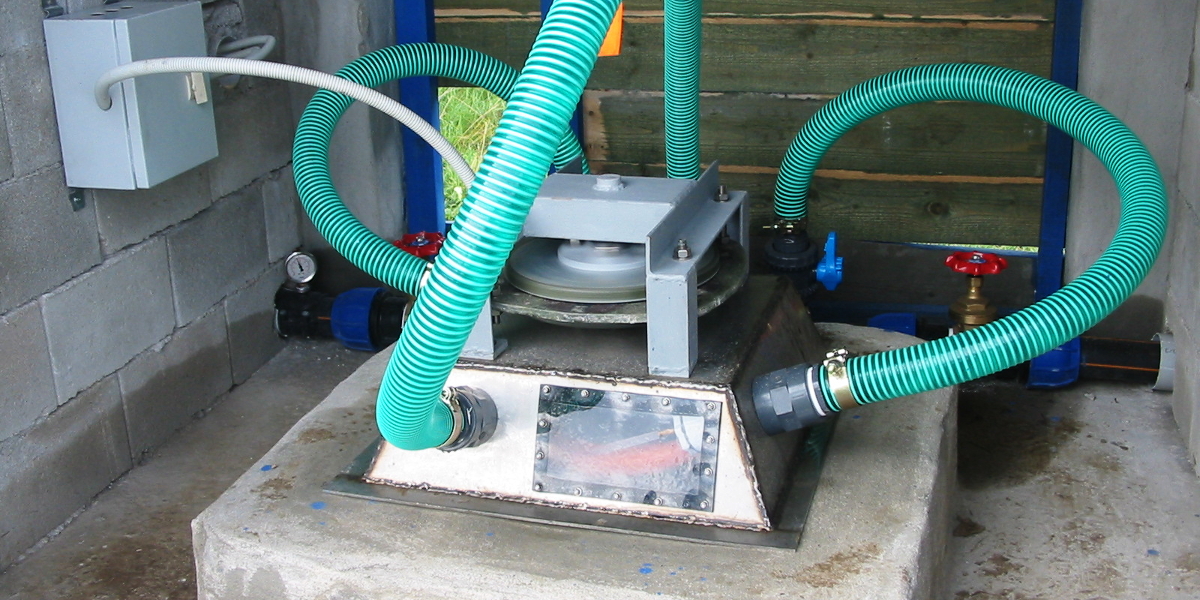

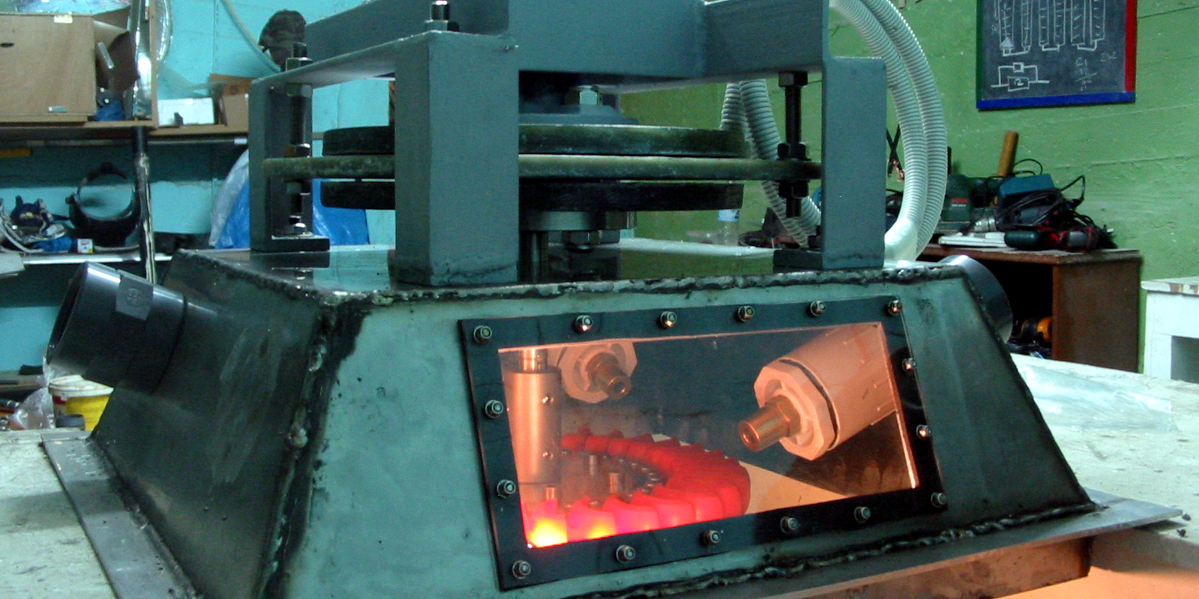

Small hydro technology offers one of the most economical sources of electricity generation in stand-alone renewable energy systems. The basic operating principle is the conversion of the kinetic energy of water into electricity using the hydro turbine and generator. In rural areas with good hydrological potential, such as mountainous areas of mainland Greece for example, autonomous power generation systems can base their entire production on a small hydro-generator. Areas with good hydrological potential are usually locations with running water such as small rivers and streams, in places with moderate to steep slopes. A characteristic of all rotating parts machines is the need for regular maintenance, although this is less true for hydro generators than for small wind turbines, because they are not exposed to the weather and operate with a constant water supply as opposed to the highly variable nature of the wind. One of the main reasons that the Energy Laboratory has chosen to use locally made small hydro generators is that they enable the user to undertake their maintenance with minimal knowledge and using common tools and simple materials that can be purchased locally. In addition, the market for small hydro generators is not as large as that for small wind turbines, so the products available on the market are limited and costly. This technological application has been developed by New Guinea in collaboration with the Rural Electrification Research Group (RurERG) of NTUA and is a combination of the construction of generators described in Hugh Piggott’s ‘A Wind Turbine Recipe Book’ and the use of turgo hydro turbines made by Joe Hartvigsen (h-hydro.com). The first locally manufactured small 500W hydrogenerator was installed in a mountain farm in Oiti in the spring of 2013 and has been operating daily around the clock since then, having now exceeded 35 thousand hours of maintenance-free operation. New Guinea’s small hydro generator workshops aim to provide participants with a wealth of practical skills and an understanding of the basic principles of a small hydro generator, while producing an efficient and reliable product.

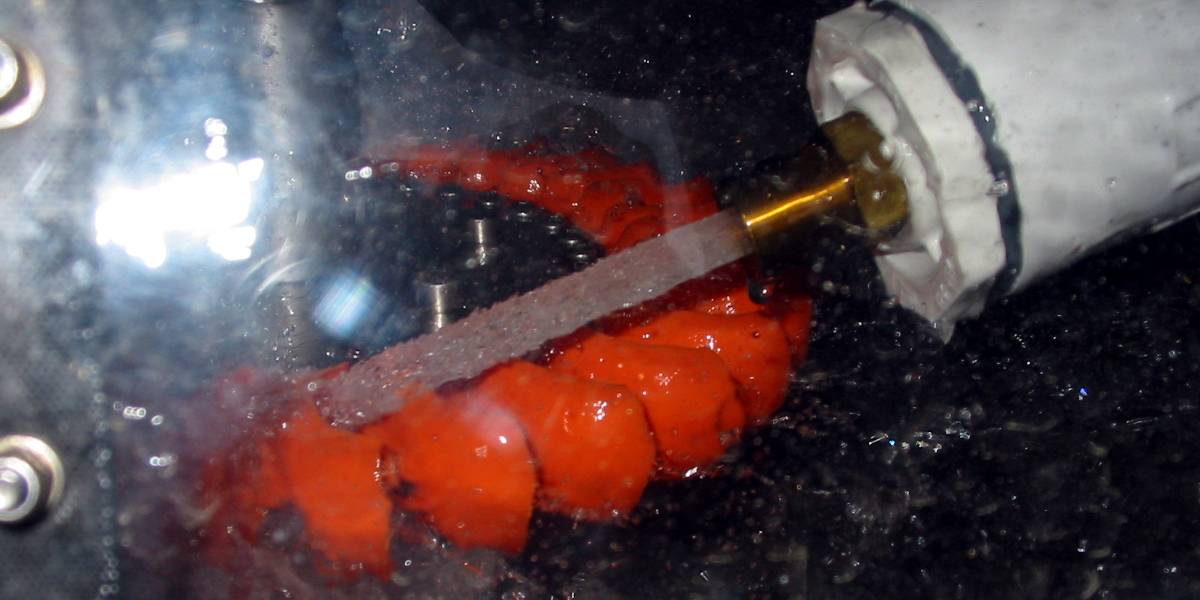

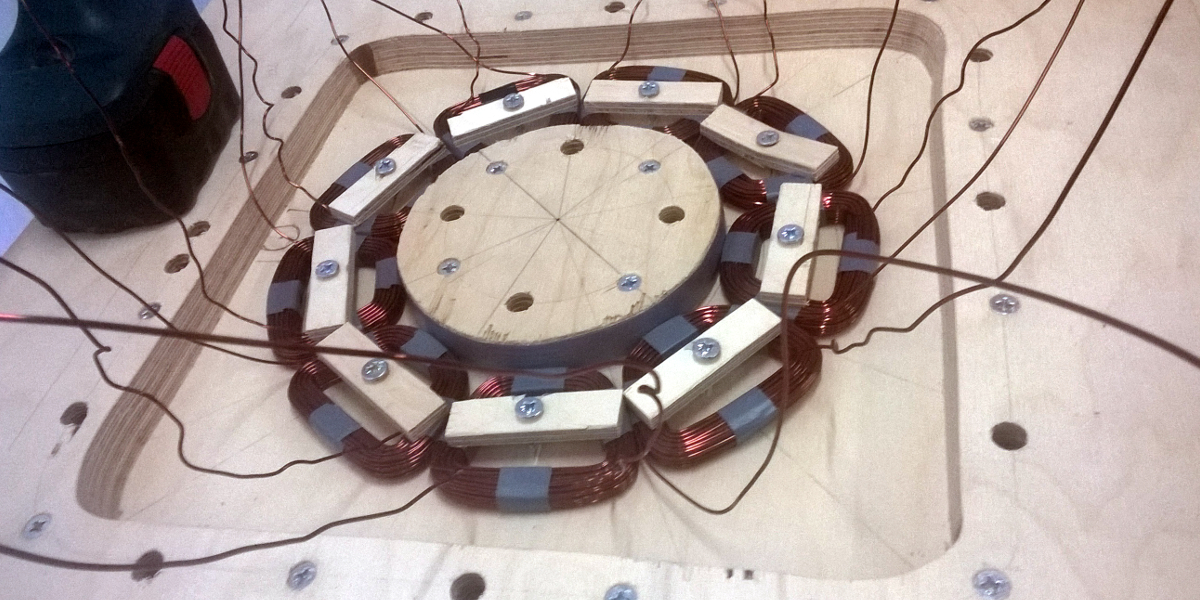

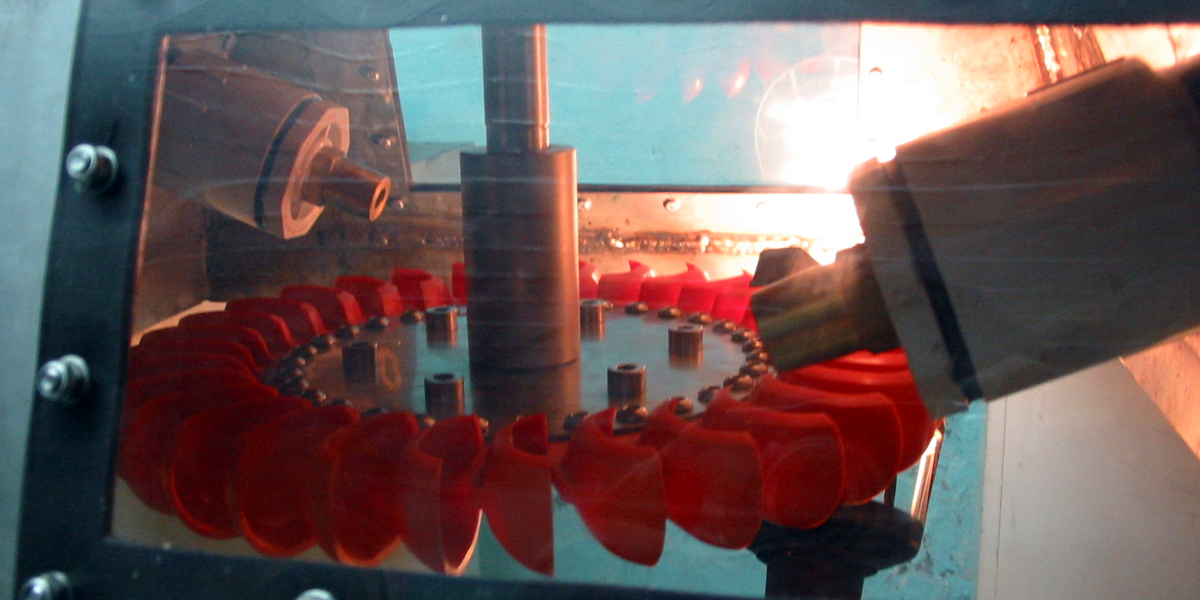

The courses include the construction of handmade hydrogenerators of nominal power from 500W and consist of the following practical parts: familiarization with the basic tools, construction of the generator stator and its coils, construction of the generator rotor and magnet discs, construction of the moulds for moulding the generator parts with polyester resin, iron construction for supporting the generator and the turbine, printing of the hydro turbine with the Prusha i3 3D printer and assembly and adjustment of the generator. The hydro-generators built during the seminars are used in outdoor electrification applications, and usually the person or group that will eventually use the hydro-generator will finance the project with the cost of the materials.